Our Activities

Our company deals with a wide range of measurement tasks in various sectors of industry.

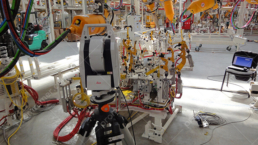

- Incoming inspection of hydraulic components (runner, shaft, stator, rotor, crosspiece).

- Support for assembly of hydraulic units, virtual assembly.

- Installation of stator wedges.

- Inspection of spiral casing.

- HPP.

- Assembly of hydraulic units.

- Inspection of workbenches, jigs, assembly tooling, fixtures, die sets.

- Inspection of finished products.

- Leveling.

- Projection of livery when painting aircraft.

- Aircraft scanning and 3D modeling.

- Measurement of jigs, geometry inspection of jigs.

- Determination of the mill axis inclination.

- Determination of the drive axis inclination, turn and tilt.

- Support for mill adjustment and installation.

- Measurement of inclination of bedplates.

- Alignment of mills.

- Support for equipment installation.

- Installation, adjustment of sole plates and embedded parts.

- Inspection and alignment of main parts of paper machines, cardboard machines and corrugators.

- Alignment of other pulp and paper equipment.

- Alignment of sheet-rolling shop (geometry inspection of stands, geometry inspection of coiler section, inspection of run-in and run-out tables).

- Inspection of continuous-casting plant, modeling, adjustment of rollers.

- Alignment of continuous-casting machines.

- Alignment and adjustment of welding benches.

- Geometry inspection of die sets, jigs, vehicle body.

- Shape inspection of tires and support rollers.

- Alignment and commissioning of rotary kilns, coolers, nodulizers, dryers.

- Central angles and geometry of the spatial position of rotation axes of support rollers and tires on all supports of a rotary kiln.

- Turns and slopes of support rollers of a rotary kiln.

- Measurement of components, sections, blocks both during and after completion of manufacturing and construction.

- Application of check points for painting.

- Marking of a slipway and axes of the centerline, baseline and frames to create the coordinate system of a vessel or a ship during its construction.

- Quality control of assembly jigs.

- Jig operations to position sections and blocks in the vessel’s coordinate system.

- Shape and dimension check of a vessel’s hull under construction.

- Geometry inspection of supporting and mating surfaces of vessel foundations for main and auxiliary mechanisms, shafting, equipment, and devices.

- Marking the position of main and auxiliary mechanisms, shafting, equipment, and devices.

- Alignment of elements. Surface inspection for all surface shapes. Diameter determination.

- Determination of the radius relative to the geometric axis of the part.

- Concentricity of elements. Surface roughness.

- Inspection of the positional location of hole centers.

- Alignment of the centers of the control elements of the shaft.

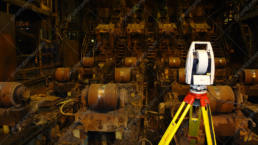

3D scanning

- 3D scanning of buildings, objects, and industrial structures.

- Visual analysis and measurements based on scan data.

- Creation of actual CAD models based on scanning results.

Measurements, especially high-precision ones, are a highly specialized task. However, various industries constantly face the need for accurate industrial measurements. Measurements are necessary in completely different cases: from the lack of information about the object to the manufacture of a precise model of a part.

Our company’s main activity is metrology that is not subject to licensing.

We guarantee professional competence, equipment and other material capabilities required for high-precision measurements.

All measuring equipment that we use in our work is listed in the State Register of Measuring Instruments and has a government-issued certificate of verification.

All our professionals completed specialized training in working with hardware and software, which is evidenced by certificates.

Contact us for accurate and trustworthy results!

Расскажите о проекте

Мы обязательно свяжемся с вами в течение 1 рабочего дня и подготовим всю интересующую вас информацию!