You are able to download printable version of this article in .pdf format for offline use!

Automotive Sector

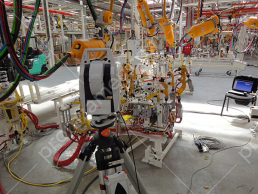

About the automotive industry, measurements, welding stands, posts, stations

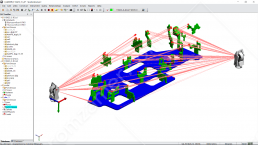

Modern automotive technologies require high accuracy of geometry of the vehicle body and individual components and, accordingly, impose more stringent requirements for:

- welding benches;

- jigs;

- die sets, male dies, female dies;

- inspection fixtures;

- vehicle components.

Modern CMMs assure high accuracy of measurements. Leica laser trackers offer accuracy of 0.015 mm±0.006 mm/m. The Hexagon CMM arm offers accuracy of 0.008 mm across the entire measurement range.

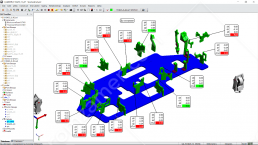

Geometry inspection of basic pins (clamps)

Basic clamps of an assembly line are an important stage in the commissioning of a conveyor since, as a vehicle body moves from station to station, the basic clamps must ensure the uniqueness of the installation of the body in a station’s coordinate system to ensure the correct geometry of the body during welding.

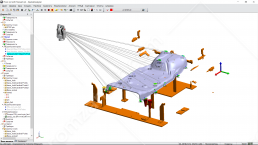

Geometry inspection of a vehicle body

Modern tools and methods of geometry inspection reduce inspection operation time and completely replace templates, inspection fixtures and references, thus moving away from the manufacture of inspection fixtures during subsequent upgrade.

Tell us about your project

We will contact you in 1 working day and prepare the info you need.