You are able to download printable version of this article in .pdf format for offline use!

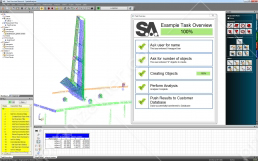

SpatialAnalyzer® Training

We will hold consultations on working with the SpatialAnalyzer software and discuss all topics of interest to you in detail.

About training

We will demonstrate examples of using software functions in your enterprise during training. We also offer custom-designed training classes to fit your individual needs.

Duration and types of training programs:

A standard basic SpatialAnalyzer training program is a five-day course held at the customer’s site using the customer’s equipment in a group of up to six people.

A custom-designed SpatialAnalyzer training program is a minimum three-day course held at the customer’s site using the customer’s equipment in a group of up to six people.

A standard extended SpatialAnalyzer training program is a five-day course held at the customer’s site using the customer’s equipment in a group of up to six people.

A custom-designed extended SpatialAnalyzer training program is a minimum three-day course held at the customer’s site using the customer’s equipment in a group of up to six people.

Below you can find the main topics and blocks of SpatialAnalyzer training courses. The knowledge you gain from training will allow you to achieve the required measurement results and speed.

Alignment.

Working with multiple instruments.

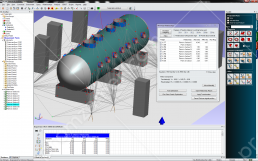

SpatialAnalyzer can simultaneously connect to almost any number and type of portable metrology instruments, such as laser trackers, portable CMM arms, laser radars, scanners, projectors, theodolites, total stations and photogrammetric devices.

To use multiple instruments simultaneously, SpatialAnalyzer also has its own toolkit that allows you to measure with all instruments at the same time. You can move an object in real time with coordinates displayed, etc.

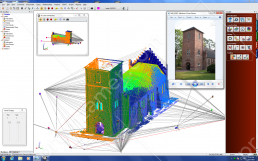

Scanning. Working with point clouds.

Virtual assembly of components and assembly in real time.

GD&T module.

Calculating measurement uncertainties using the USMN module.

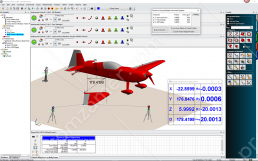

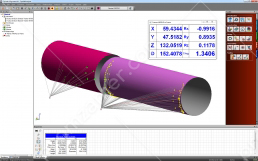

Geometry inspection.

Report generation tools.

Automation.

The use of measurement plans and the SDK provides powerful capabilities for automating measurement processes, processing obtained data and generating reports. Auto measurement modes and associated callouts. All this enables less experienced operators to perform and manage complex processes of measurements and data processing based on a script prepared for them in advance.

Tell us about your project

We will contact you in 1 working day and prepare the info you need.